Autumn Garden Gate Maintenance: Essential Autumn Prep Before Winter Arrives

- Gates

- Railings

- Fencing

- Accessories

& Fitting- Sheds

& Storage- Garden Structures

- Design

& StyleMetal Gates & Railings- Info

& HelpOctober marks the crucial window for gate maintenance. British winters test gates harder than most homeowners realise – months of rain, frost cycles, and wind take their toll. Gates neglected in autumn face accelerated deterioration through winter, often requiring repairs that could have been prevented with basic preparation.

The timing matters more than the specific tasks. October weather remains mild enough for maintenance work while giving materials time to cure before winter sets in. Leave it until November and conditions become less reliable. Wait until problems emerge in January and damage has already occurred.

Gate maintenance differs significantly from general garden upkeep. These structures bear mechanical loads, face weather from all angles, and combine multiple materials that deteriorate at different rates. Understanding what needs attention and why prevents both over-maintenance and costly neglect.

Assessing Current Condition

Start with thorough inspection rather than jumping into tasks. Many gates show subtle deterioration signs that become serious problems under winter stress. Walking past gates daily means gradual changes go unnoticed until something fails.

Check how gates hang when closed. They should sit square in the frame without binding or gaps. Misalignment indicates hinge wear, post movement, or structural issues that will worsen through winter. Small problems now become major repairs later.

Test the full range of motion. Gates should open and close smoothly without scraping, sticking, or requiring excessive force. Resistance suggests hinge corrosion, ground clearance issues, or frame distortion. These problems compound rapidly once frost and rain begin.

Examine all fixings and fasteners carefully. Rust stains around screws indicate moisture penetration. Loose bolts suggest movement has occurred. Missing fixings mean loads have redistributed onto remaining attachments. Winter weather exploits these weaknesses ruthlessly.

Look for wood deterioration if dealing with timber gates. Soft spots indicate rot establishing itself. Surface cracks allow moisture deeper into timber. Peeling paint or stain exposes bare wood to winter elements. These issues accelerate dramatically once frost cycles begin.

Metal components require equally careful inspection. Surface rust looks superficial but indicates protective coatings have failed. Corrosion around welds suggests structural weakness developing. Loose metalwork rattling in wind causes accelerated wear at fixing points.

Wood Gate Preparation

Timber gates need the most intensive autumn preparation. Wood responds dramatically to moisture content changes, and winter brings sustained wetness that summer never matches.

Clean thoroughly before any treatment work. Dirt and organic matter trap moisture against timber surfaces. Power washing seems efficient but forces water deep into grain structure. Brush cleaning with mild detergent solution works better for most situations.

Allow proper drying time after cleaning. Applying treatments to damp timber wastes product and reduces effectiveness. October often provides dry spells suitable for this work. Check weather forecasts and plan accordingly.

Treatment choice depends on existing finish and timber type. Pressure-treated softwood already contains preservatives but benefits from additional surface protection. Bare hardwood requires oil-based treatments that penetrate deeply. Previously painted gates need paint system maintenance rather than oil treatments.

Apply treatments generously to end grain and joints. These areas absorb moisture fastest and deteriorate first. Multiple thin coats outperform single heavy applications. Allow proper drying between coats regardless of product claims about recoat times.

Pay particular attention to bottom rails and any horizontal surfaces. These collect water and shed it slowly. Extra treatment here extends gate life significantly. Don't neglect areas where timber contacts metal fittings – these junctions concentrate moisture.

Check all timber joints for movement. Mortise and tenon joints can loosen over time. Ledge and brace construction relies on diagonal bracing remaining tight. Loose joints allow gates to distort, which then prevents proper closing and accelerates overall deterioration.

.jpg)

Metal Gate Care

Metal gates resist weather better than timber but still require autumn attention. Corrosion that starts in autumn progresses rapidly through winter.

Remove all loose rust and failing paint. Wire brushing works for minor surface corrosion. More serious rust requires more aggressive treatment. Getting back to sound metal matters more than preserving existing finish.

Treat bare metal promptly after cleaning. Rust converters stabilise existing corrosion. Metal primers provide base protection. Top coats add weather resistance and appearance. Each layer serves a specific purpose – skipping steps compromises the entire system.

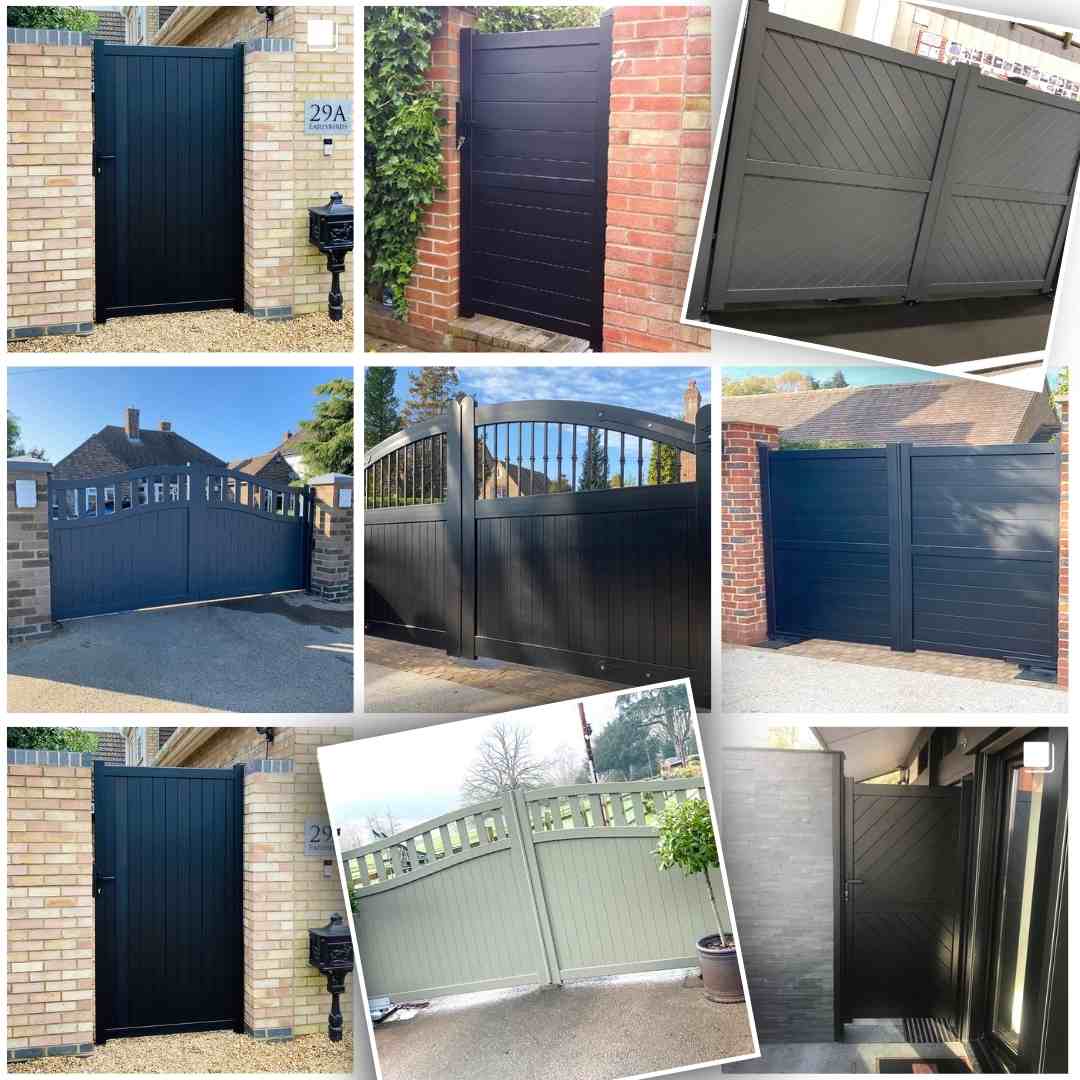

Galvanised and powder-coated gates need less intensive treatment. Inspect coatings for damage rather than assuming protection remains intact. Small chips in powder coating allow corrosion to start beneath the surface. Touch up damage promptly before it spreads.

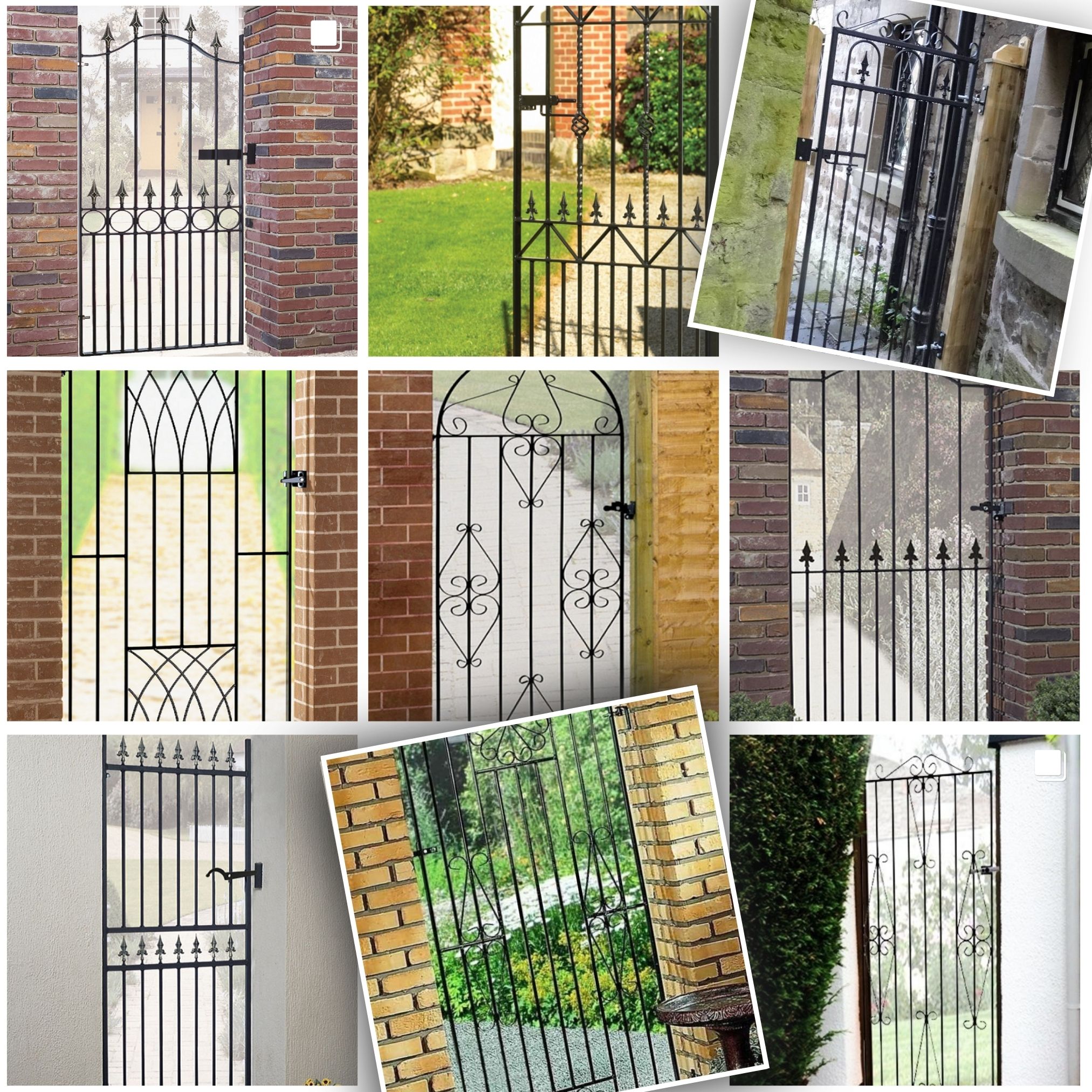

Wrought iron and decorative metalwork collect moisture in ornate details. These areas corrode first. Clean thoroughly and ensure treatment reaches all surfaces. Neglected decoration becomes the weak point that compromises entire gates.

Check welds and joints carefully. Corrosion often starts at these junctions where different metals meet or protective coatings were compromised during fabrication. Early treatment prevents structural problems developing.

Aluminium gates corrode differently than steel but still need attention. White powdery deposits indicate corrosion beginning. Clean and treat these areas. Aluminium corrosion accelerates once started.

Hardware and Mechanisms

Gate hardware bears all the mechanical loads and faces full weather exposure. This combination makes hardware particularly vulnerable to winter damage.

Hinges require careful assessment. Check for play in the hinge pin. Excessive movement indicates wear that will worsen under winter loads. Listen for squeaking or grinding – these sounds mean lubrication has failed and metal surfaces are wearing.

Clean hinge mechanisms thoroughly before lubricating. Old grease mixed with dirt creates grinding paste that accelerates wear. Remove everything and start fresh. Use appropriate lubricants – light oils for frequent-use gates, heavier greases for gates opened less often.

Latches and locks face different challenges. Mechanisms exposed to weather need protection from moisture while maintaining smooth operation. Graphite powder works better than oils for locks. Stainless steel components outperform standard hardware in exposed locations.

Check latch alignment carefully. Gates that have dropped or posts that have moved cause latches to bind. This creates additional stress on both latch and gate structure. Adjustment now prevents forcing mechanisms through winter.

Posts and Foundations

Gate posts carry all loads and determine how well gates function. Post problems affect everything else.

Check posts for movement. Push firmly at the top – any flexing indicates foundation issues. Movement here means gates cannot hang properly regardless of hinge condition. Winter frost action makes post movement worse.

Examine post bases carefully. Wood posts often rot where they meet ground level. Metal posts corrode at the same junction. These problems hide until they become serious. Probe with a screwdriver to check wood soundness. Look for rust staining around metal post bases.

Concrete haunches around posts should remain solid and well-attached. Gaps between concrete and post allow water penetration. Frost then expands in these gaps, forcing posts loose. Repair small gaps now before frost begins.

Post caps keep water out of hollow metal posts and off timber post tops. Missing or damaged caps allow water inside structures. This trapped moisture causes internal corrosion or rot that's invisible until serious. Replace damaged caps promptly.

Consider post bracing for exposed locations. Winter winds test posts harder than summer breezes. Additional support prevents gradual loosening that accumulates over seasons.

Ground Clearance and Operation

How gates interact with ground surfaces affects both operation and longevity. Winter changes these relationships.

Check clearance under gates when fully closed. Insufficient clearance causes binding as ground softens or frost heaves occur. Scraping wears gate bottoms and damages mechanisms. Aim for consistent clearance along the entire bottom edge.

Look at gate paths across driveways or paths. Uneven surfaces cause gates to catch during operation. Low spots collect water that then freezes, preventing proper closing. Address drainage issues now rather than fighting ice through winter.

Automated gates require particular attention to ground clearance and obstructions. Safety sensors work poorly in wet conditions. Sliding gate tracks must remain clear and properly drained. Winter debris and ice cause expensive damage to motors and mechanisms.

Test gates through complete operation cycles. Don't just check closed position. Gates that open smoothly but catch when closing indicate specific issues. Full cycle testing reveals problems casual observation misses.

Final Preparations

Beyond specific component maintenance, several general preparations help gates survive winter better.

Clear vegetation around gates and posts. Plants trap moisture against structures and restrict air circulation. This creates perfect conditions for rot and corrosion. Cutting back now prevents problems developing.

Ensure drainage works properly around gate posts and along gate paths. Standing water accelerates all deterioration processes. Winter adds freeze-thaw cycles that compound damage. Improve drainage before ground becomes saturated.

Consider temporary measures for extreme exposure situations. Some properties face conditions that overwhelm normal protection. Additional covers, windbreaks, or seasonal reinforcement may be justified for valuable gates in harsh locations.

Document current condition with photographs. This creates baseline records for tracking deterioration and proves useful when problems develop. Photos also help when discussing repairs with professionals or insurance companies.

When Professional Help Makes Sense

Some maintenance tasks require professional expertise or equipment. Recognising these situations prevents both inadequate repairs and dangerous DIY attempts.

Structural repairs to gates or posts often need professional attention. Welding, major timber repairs, or foundation work requires proper equipment and skills. Amateur attempts frequently make problems worse.

Automated gate systems should receive professional service. These systems involve electrical components, safety features, and complex mechanisms. Incorrect maintenance causes failures and safety hazards.

Major refinishing projects benefit from professional equipment and experience. Powder coating, hot-dip galvanising, or complete paint stripping exceed typical DIY capabilities. Professional results last longer and protect better.

The October Advantage

Completing maintenance during October provides several advantages beyond just beating winter weather. Materials cure properly in moderate temperatures. There's time to address problems discovered during inspection. Supply chains remain normal for any required parts or materials.

Gates that receive proper autumn maintenance face winter from a position of strength rather than existing compromise. Small investments in October prevent large expenses in spring. More importantly, gates continue functioning reliably through the season when access matters most.

The difference between maintained and neglected gates becomes starkly apparent by February. Maintained gates operate smoothly despite weather. Neglected gates stick, sag, corrode, and eventually fail. October preparation determines which category gates fall into.

- Railings